Website-Einstellungen

Produkte

Produkte

Leistung

HF

Transformatoren

Tools für Design-Support

Nutzen Sie unsere ‚Suite of Tools‘ für die Auswahl, die Analyse und den Vergleich von Induktivitäten

Alle Tools anzeigen

Parametrische Suche

Lassen Sie sich die Liste unserer Induktivitäten und Filter zu Ihren Parametern anzeigen.

Erforschen

Datenblätter

Sie suchen nach einem Datenblatt? Suchen Sie nach Produkt und laden Sie das PDF herunter

Liste anzeigen

Automobiltechnik

Informationsmaterial

![YouTube preview image]()

![YouTube preview image]()

![YouTube preview image]()

![YouTube preview image]()

Informationsmaterial

Produktdokumentation

Handhabung und Verarbeitung

Modelle und Layout-Tools

Kurse/Schulung

Video-Bibliothek

Cx Family Common Mode Chokes

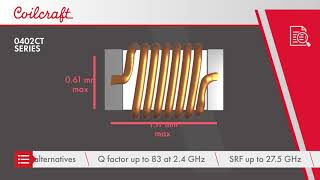

0402CT Low Profile Chip Inductors

XAL7050 High-inductance Shielded Power Inductors

XGL4020 Ultra-low DCR Power Inductors

Student Support

Learn more about magnetics, request free samples or ask our engineers a question.

Get Support

Quality

Quality

Qualitätszertifizierung

Materialzertifizierung

Sicherheitszertifizierung

Zuverlässigkeit

Handhabung / Verarbeitung

Über

Über

Über

Jobs

Standorte

Informationsmaterial